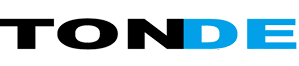

Overview of Palm Biomass Wastes

There are various materials that are potential sources for biomass pellets making. Take oil palm wastes as an instance. In oil palm industry, when the fresh palm fruits are harvested, a large number of wastes are left, which include empty fruit bunch (EFB), palm kernel shell (PKS), oil palm frond (OPF), oil palm trunk (OPT) and oil palm mesocarp fiber (OPMF). In traditional, some of these wastes are used as organic fertilizer, some are burned for heating, and some are just left. However, these methods are not the most economical solutions. In fact, most of these wastes from oil palm can be properly utilized. The processing method commonly used in making them into pellets or briquettes and then they can serve as fuel. Thus the added value of oil palm wastes is produced.

Types of Oil Palm Biomass Exist in Plantations and Mills (Note: CPO refers to Crude Palm Oil)

| Types | Description | Site |

| EFB | Remains after removal of palm fruits | Plantation |

| PKS | Remains after palm kernel oil exaction | Mill |

| OPF | Leaves of oil palm tree | Mill |

| OPMF(Fiber) | Remains after CPO extraction from fruit bunches | Mill |

| OPT | Tree trunks available at end of plantation life cycle | Plantation |

It is calculated that, harvesting 1 ton of fresh oil palm fruit, requires removal of 1,900 kg of fronds. Processing 1 ton of fresh fruit bunch gives 200 kg of empty fruit bunch (EFB), 70 kg of palm shells and 220 kg fiber. So quite a large amount of wastes from oil palm can be employed.

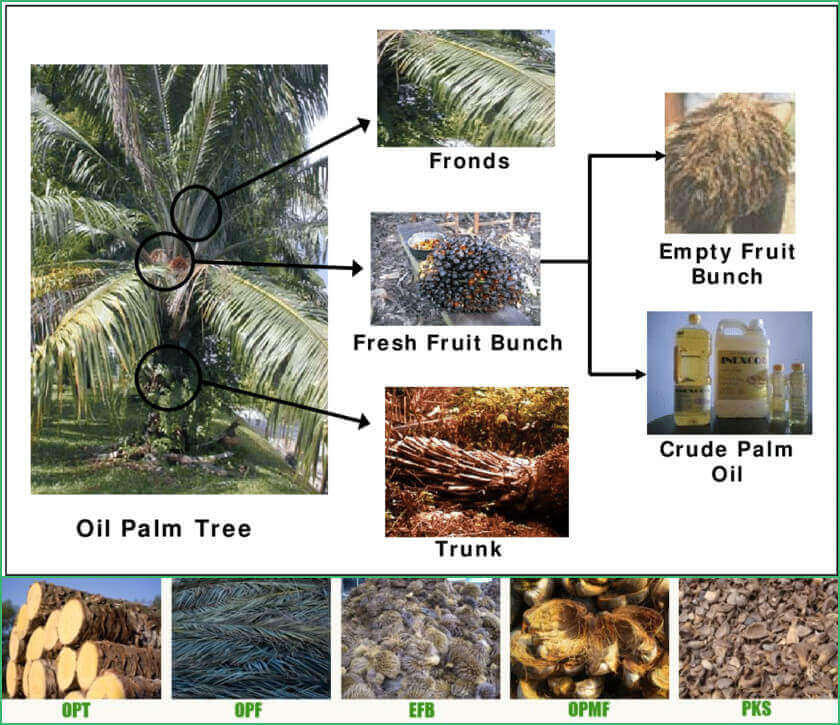

Pelletizing Process of Oil Palm Wastes

All these wastes from oil palm can be processed into pellets and used as clean energy. Making them into biomass pellets is a wise decision. The wastes from oil palm can be processed into biomass pellets until a series of steps including crushing, drying, pelleting, cooling and packing are performed. As for the detailed process, here take the EFB pellets and PKS pellets as examples.

1. EFB Pelletizing Process

2. PKS Pelletizing Process

The material PKS can be made into biomass pellets when several steps are done. First CRUSHING by a hammer mill (or crusher), then PELLETIZING by a pellet mill, next COOLING by a cooler, finally PACKING by a packing machine.

Property of Main Palm Biomass Wastes

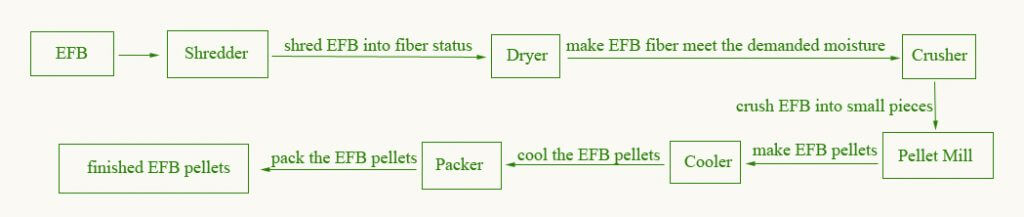

1. EFB fuel

Empty Fruit Bunch (EFB) refers to the bunch without fruit, which is discarded from rude palm oil mill. And it can be processed into EFB pellets (briquettes or charcoals), the diameter of which should be from 6mm to 10mm and the length should be less than 30mm.

| EFB | EFB pellets/briquettes | |

| Moisture content | about 38% | <12% |

| Volatile | about 46% | about 75% |

| Fixed carbon | about 12% | about 13% |

| Ash content | about 4.5% | about 5% |

| Calorific value | about 4,400kcal/kg | about 4,000kcal/kg |

| Diameter | 6,8,10mm etc. | |

| Length | <30mm |

2. PKS fuel

PKS is the waste material from production of crude palm oil. Compared to other residues from the industry, it is a quality biomass fuel with uniform size, and it is easy to handle and crush. The properties of PKS and PKS pellets or charcoals are shown as follows:

| PKS | PKS pellets | |

| Moisture content | about 12% | <12% |

| Volatile | about 68% | about 75% |

| Fixed carbon | about 16% | about 13% |

| Ash content | about 3.5% | about 5.3% |

| Calorific value | about 4,000kcal/kg | 3,814-4,724kcal/kg |

| Diameter | 8-12mm |

Advantages of Palm Biomass Waste Pellets

◊ There is a large amount of oil palm wastes in several oil palm producers, such as Malaysia, Indonesia. So, the sources for oil palm waste pellets are quite abundant. Also, the materials are mainly distributed in the oil pal processing plants, suggesting that they are easy to collect.

◊ The biomass pellets made from oil palm wastes are of good quality after several steps.

◊ The biomass pellets made from oil palm wastes are with high heating energy and efficiency. The pellets normally come in the boiler with a diameter of 8 diameters and a length of about 20-30mm. This is suitable for most of the boiler input grate.

◊ These biomass pellets can be applied widely, and the demand for them is increasing.

◊ They are friendly to the environment. While being burned, the biomass pellets from oil palm wastes do not generate sulfur dioxide nor phosphoric anhydride since they do not contain phosphorus or sulfur. Due to this, oil palm pellets do not pollute the atmosphere nor pollute the environment.

◊ The biomass pellets made from oil palm wastes are easy to transport, handle, and store.

Application of Palm Biomass Waste Pellets

Palm biomass as one of the readily available renewable energy sources is gaining attention for power generation due to its heat energy content. As for biomass pellets or briquettes, produced from oil palm wastes, can serve as a substitute for fossil fuels. Biomass pellets from oil palm wastes can replace or supplement traditional fossil fuels in boilers, furnaces and kilns for heat generation and power generation.

For example, many manufacturing facilities that consume a large amount of heating such as cement plants and glove factories have also switched to the use of biomass pellets or briquettes as part of their major fuel source in response to the rising fossil-fuel price. Besides, palm biomass pellets or briquettes could be the ideal renewable energy fuel source for co-firing in coal-fired power plants.

It was found that briquettes or pellets made either from 100 % pulverized EFB or mixed with sawdust exhibited good burning properties. And EFB fiber and palm kernel, due to their physical properties, were recommended to be blended with sawdust in producing quality briquettes or pellets. The application of biomass pellets or briquettes or charcoal is specifically shown below.

1. EFB pellets: As for the pelletized EFBs (i.e. EFB pellets), they can be used in power plants, biomass boilers, domestic pellet stoves, and fireplaces, BBQ, domestic cooking and central heating generation.

2. PKS pellets/charcoal: One of the most favorable used forms of PKS is to process it into the charcoal pellets. PKS pellets can be applied in: a) Power plant; b) Industrial boiler; c) Household heating; d) Brick kilns; e) Charcoal pellet burner; f) Water purification as activated carbon; g) Home use stoves; h) Barbecue fuel.

3. OPF pellets: OPF is a possible raw material to be pelletized and used in an industrial furnace.

Besides, the biomass pellets made from OPMF and OPT are also good to be used as biomass fuel.

Brief Analysis of Typical Markets

Today, oil palm grows throughout Africa, Asia, North America, and South America, with 85% of all palm oil globally produced and exported from Indonesia and Malaysia.

Biomass pellets from the oil palm industry are attractive renewable energy fuel in Southeast Asia. The abundance of these biomass resources is increasing with the rapid development of the oil palm industry in Malaysia and Indonesia, where a large quantity of oil palm trees grow there. Indonesia and Malaysia are the two largest oil palm producing countries.

Availability of Biomass Fuel from Oil Palm Wastes

| Biomass type | Availability:dry weight at 20% MC (ton/ha) |

| EFB | 1.4 |

| PKS | 0.8 |

| OPF | 9.9 |

| OPMF | 1.5 |

| OPT | 2.7 |

From the figure above, it can be concluded that the development of the oil palm industry has caused quite a number of wastes. There is good potential for biomass pellets production from oil palm wastes in Malaysia and Indonesia.

1. Malaysia

a) Status in Malaysia

Malaysia is a country with rich oil palm trees. The products from oil palm, like EFB, PKS, etc. contribute the portion of oil palm wastes. Take EFB as an example. There is 20 million ton of EFB available in Malaysia, most of which are used as raw biomass materials. Because of the large volume of EFB, Malaysia becomes an EFB pellet manufacturer.

Due to the increase in fossil fuel prices, we are seeing the need for converting oil palm waste into palm pellet. Palm pellet is a more efficient energy source compared to raw material. There are several well-established palm pellet manufacturers in Malaysia.

Of course, derivative products of oil palm wastes such as EFB pellet/briquette, PKS pellet/briquette will be more suitable for the overseas market.

b) Factors Making Malaysia A Palm Pellets Manufacturer

* Malaysia is with abundant oil palm sources. It is one of the major oil palm cultivation countries in the world. There is a large amount of oil palm biomass left behind in the palm oil mill.

* The success of the oil palm industry in Malaysia is attributed to the confluence of government and private sector strategies and policies. Every year, the Malaysian government has invested substantial funds in researching and developing new applications.

* Technology and R&D are another 2 major factors making Malaysia a palm pellet manufacturer in this district.

2. Indonesia

Indonesia also has a large area of land growing oil palm. Oil palm plantation stretches across 7.8 million hectares in 2011. And this number is still rising. Due to the rainforest, Indonesia ranks high among all countries in the oil palm industry. If all the left wastes from the oil palm industry can be made into pellets and used as energy, there should be a considerate market.

a) Distribution of oil palm trees in Indonesia

The Indonesian islands, Sumatra and Kalimantan (Borneo as the Indonesian name) are the most productive palm-growing areas in the world. Within these areas, Riau, North Sumatra, and South Sumatra in Sumatra, and Central Kalimantan, East Kalimantan, and West Kalimantan are the top palm-producing provinces of Indonesia.

b) Outlook

The oil palm industry has the potential to promote the significant economic and social development of Indonesia. It is reported that the industry provides a means of economic development for Indonesia people.

Indonesia people have gained a lot from palm oil production. Besides this, there is quite a lot of wastes from the palm oil industry. Utilizing all of the wastes from oil palm would be a wise choice since there truly exists a substantial market. If so, the Indonesia people will benefit from this a lot.